Displacement

measurement using LDR

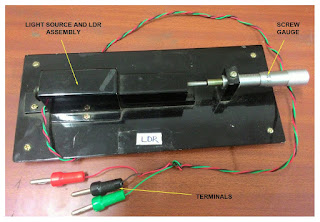

Setup:

The complete setup consists of a sensor module and its signal

conditioning circuit. In the sensor module there is an LDR and a light source

enclosed inside a metallic enclosure. There is a 20 mm screw gauge to provide

known displacement. A rod is connected to the LDR inside the enclosure and it

is attached to the screw gauge outside. Hence we can provide known displacement

to the LDR by the screw gauge. Three terminals are attached to the sensor module,

Vcc and GND for the light source and one terminal of LDR w.r.t ground. The output

of the sensor module is fed to the signal conditioning and processing unit. There

is a IC regulated power supply source that provides constant voltage to all the

circuits for their functioning. A zero adjustment and gain adjustment pot is

there for calibration purpose. And there is a four 7 segment LED display which

shows the output directly in mm.

Working:

LDR stands for Light Dependent Resistor, it is basically a resistor

whose resistance depends upon light intensity. And the relation is inversely proportional

means when the light intensity is more the resistance is less and vice versa. The

LDR is attached to the rod at one end inside the enclosure. The light source

has been kept fix. When the screw gauge is rotated it gives a linear

displacement to the rod attached to it. This displacement changes the distance

between light source and LDR. When the distance is less the resistance of LDR

is less and when the distance is more the resistance will be more. This change

of resistance is given to the signal conditioning circuit where it is

calibrated to give the output directly in mm.

Procedure:

Connect the LDR sensor leads with the trainer kit terminals according

to their colors. Switch ON the power. Keep the DPM switch at mm position. Connect

a patch cord between output terminal and DPM terminal. Keep the micrometer at

zero position and adjust zero pot to set zero reading on the display, set the

micrometer at 15mm and adjust the adder pot to show 15mm on the display. Now increase

the micrometer in steps of 1 mm and note down the in following table in

increasing and decreasing mode. Plot the graph between micrometer reading and

DPM reading in mm.

Observation:

Sl no

|

Reading in

increasing mode

|

Reading in decreasing mode

|

||

Micrometer

reading (mm)

|

DPM

reading (mm)

|

Micrometer

reading (mm)

|

DPM

reading (mm)

|

|

Displacement measurement using linear pot

Setup:

The setup has a linear pot and a screw gauge arrangement module and

its signal conditioning circuit. The linear pot is a sliding type potentiometer

enclosed inside a metallic enclosure. A rod is attached to the sliding arm of

the potentiometer at one end and to the screw gauge at the other end. Three terminals

are taken out from the sensor (pot), one for Vcc one for GND and another for

output from the wiper of the pot. These three terminals are connected to the

signal conditioning where the output is processed and calibrated in terms of

displacement. In the signal conditioning unit there is an IC regulated power

supply source that provides constant voltage to all the circuitry inside the

unit and to the pot also. There is a zero and span adjustment pot for

calibration. And a four 7 segment LED display screen.

Working:

The pot is generally a variable resistor. It has three pin/ terminal,

two are fixed and one is sliding. Between two end terminals the resistance is

fixed/constant, and between the sliding terminal and the fixed terminal the

resistance is variable according to the position of the sliding arm. The resistance

between the sliding arm and any one of the fixed terminal is depends upon the

physical distance between them. If the distance is more the resistance will

more and vice versa. If a constant voltage is applied between the two fixed terminals

the pot creates a voltage divider circuit itself. The output voltage between

sliding terminal w.r.t GND depends upon the resistance which eventually depends

upon the position of the slider. The rod connected between the slider and the

screw gauge provides the known displacement to the slider of the pot. The output

voltage is further processed and calibrated in terms of displacement.

Procedure:

Connect the linear potentiometer leads with the trainer kit terminals according

to their colors. Keep the DPM switch at mm position. Connect patch cord between

output terminal and DPM terminal. Switch ON the trainer kit. Keep the

micrometer at zero position and adjust zero pot to set zero reading on the

display, set the micrometer at 20mm and adjust the adder pot to show 20mm on

the display. Now increase the micrometer in steps of 1 mm and note down the in

following table in increasing and decreasing mode. Plot the graph between

micrometer reading and DPM reading in mm.

Observation:

Sl no

|

Reading in

increasing mode

|

Reading in decreasing mode

|

||

Micrometer

reading (mm)

|

DPM

reading (mm)

|

Micrometer

reading (mm)

|

DPM

reading (mm)

|

|

Displacement measurement using strain gauge transducer:

Setup:

In the setup the transducer used for displacement measurement is

strain gauge. The transducer module consists of four strain gauges with some

mechanical arrangement to measure linear displacement provided by a screw

gauge. In the mechanical arrangement a steel plate (measuring scale) is used,

four strain gauges are fixed over it, two on each side. One end of the scale is

fixed, but the other is exposed to linear force. A conical shaped plastic

object having 3cm length and 1.5cm dia is fixed at one end of the rod, and the

other end of the rod is attached with the screw gauge. The four strain gauges

form a Wheatstone bridge so four leads are taken out of the transducer for

electrical connection. These four leads are connected to the signal

conditioning unit. In the signal conditioning unit there is an excitation

source, some electronics circuitry, a zero adjustment and span adjustment pot

for calibration and a four 7 segment display unit.

Working:

The linear displacement provided by the screw gauge is converted in to

the linear force by the conical plastic object, which is then converted in to

change in resistance of the strain gauge by the steel plate. This resistance

change causes voltage change in Wheatstone bridge output which is further

processed and calibrated in terms of linear displacement. And is directly shown

in the display unit in mm.

Procedure:

Connect the transducer leads with the trainer kit terminals. Keep DPM

switch at mm position. Connect patch cord between output terminal and DPM

terminal. Switch ON the unit. Keep the micrometer at zero position and adjust

zero pot to set zero reading on the display, set the micrometer at 20mm and

adjust the adder pot to show 20mm on the display. Now increase the micrometer

in steps of 1 mm and note down the in following table in increasing and

decreasing mode. Plot the graph between micrometer reading and DPM reading in

mm.

Observation:

Sl no

|

Reading in

increasing mode

|

Reading in decreasing mode

|

||

Micrometer

reading (mm)

|

DPM

reading (mm)

|

Micrometer

reading (mm)

|

DPM

reading (mm)

|

|

The procedure isn't full maybe you can try add more strain gauge theory and think about this

ReplyDelete